Pneumatic hose technology faces is a sign of pneumatic industrial development. Application of pneumatic components mainly for two aspects: maintenance and support. Past domestic sales of pneumatic components to be used for maintenance, in recent years, as the main supporting directly increase the share of sales each year. Application of pneumatic components made in China, from the value of tens of millions of metallurgical equipment to only 1 to 2 hundred chairs. Railway pull fork, machine wheel rail lubrication, train brakes, street sweeping, special workshop lifting equipment, military command vehicle and so spend a specially developed domestic pneumatic air hose. This shows that the pneumatic technology has "infiltration" into all walks of life, and is growing.

Pneumatic tubing is a resilient, flexible and durable manufactured material that can take the place of paint, cotton, rubber, metal or wood in thousands of applications across virtually all fields. Pneumatic tubes also have PU and PE ,most polyurethane is for air.

2016年1月30日星期六

2016年1月25日星期一

phenomenon is termed hydraulic shock

Hydraulic system in sudden start, stop, when shifting or reversing, the sudden closure of the valve port or action suddenly stops moving parts due to the flow of liquid and the role of inertia, so that the formation of high peak instantaneous pressure in the system, this phenomenon is termed hydraulic shock. The emergence of hydraulic shock could cause greater damage to the hydraulic system, the system pressure, high speed and large flow of its more serious consequences. Therefore, when the operation to try to avoid the formation of hydraulic damper.

2016年1月21日星期四

Pu tube pneumatic industry preferred pneumatic pressure hose

Spiral hose is corrugated spirally arranged tubular housing between two adjacent corrugations have a helix angle, all the ripples can be connected by a spiral.

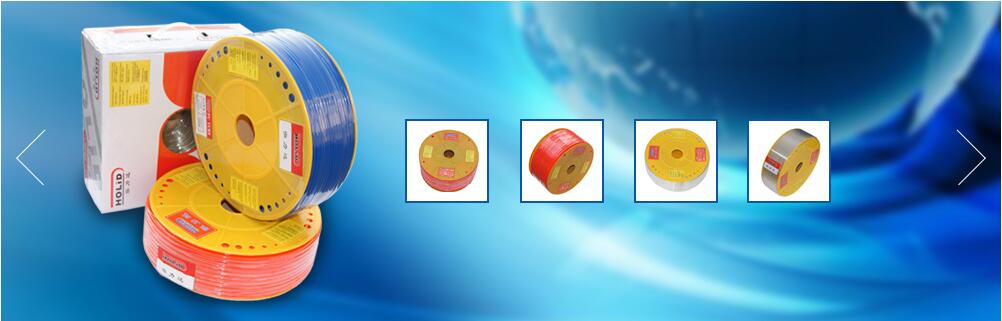

Pu tube pneumatic industry preferred pneumatic pressure hose. PU tube press material into polyester PU tube, polyether PU tube; according to the different requirements and call into PU pneumatic hose, PU grippers intensifier tubes, PU industrial hose.

Pu tube pneumatic industry preferred pneumatic pressure hose. PU tube press material into polyester PU tube, polyether PU tube; according to the different requirements and call into PU pneumatic hose, PU grippers intensifier tubes, PU industrial hose.

2016年1月17日星期日

Spiral tube sized steel

Spiral tube sized steel, wire rod, rebar, medium diameter steel pipe, steel wire and wire rope, etc., can be expected in a well-ventilated storage shed, but it must be the underlying thatch.Second,Pu pipe some small steel, sheet, strip, silicon, or thin-walled small-diameter steel pipes, all kinds of cold-rolled, cold-drawn steel products and high prices, corrosive metal products, can be stored for storage.

2016年1月13日星期三

Spiral tube with solvents

Spiral tube with solvents, emulsions, cleaning steel exterior, to reach the removal of oil, grease, dust, smoothing agents, and similar organic matter, but it does not remove the steel appearance of rust, scale, welding flux, and thus in the production of corrosion only as adjuvant trick. The primary use of wire brushes and other tools of polished steel look, you can remove loose or warped scale, rust, welding slag. Hand tools rust can reach Sa2 level, power tools rust can reach Sa3 level, if attached to solid iron oxide steel outer skin, Air tube the result is not ideal tools rust, corrosion of the anchor pattern depth of less than construction requirements.

2016年1月8日星期五

PU tube pneumatic industry preferred pneumatic pressure hose

PU tube pneumatic industry preferred pneumatic pressure hose. PU tube press material into polyester PU tube, polyether PU tube; according to the different requirements and call into PU pneumatic hose, PU grippers intensifier tubes, PU industrial hose, PU steel telescopic tube, PU spiral tube, PU telescopic tube, PU spring tube, PU tube grippers, PU braided hose, PU netted tube, PU single tube, PU straight pipes.

2016年1月4日星期一

Spiral tube of defined

Spiral tube , also known as spiral steel pipe, is low carbon steel or low-alloy structural steel strip by a certain helix angle (called molding angle) rolled into a tube, then the tube is made of welded seam, it can with a narrow strip production of large diameter pipe. Spiral is mainly used for oil, natural gas pipelines, and its specifications diameter * wall thickness. There spiral welding and double-sided welding, pipe should ensure hydrostatic testing, tensile strength and cold bending properties of the weld compliance.

订阅:

博文 (Atom)